Precision technology

Scope of service

DSM is an expert in the manufacture and implementation of precision technology for first-class assembly processes.

Below you will find a brief overview of our range of services.

Control systems

The right control system for each assembly process. DSM control systems and software are suitable for tightening and press-in tasks — the same operating concept.

DSM control systems are modularly designed and combine control electronics and a servo control in one housing.

By combining intuitive user friendliness and a modular hardware and software concept, the MultiPro 3G has created a future-oriented basis in order to overcome the current requirements in tightening and press-in technique.

Equipped with a variety of functions, the scope of services of the MultiPro 3G can be individually tailored.

DSM implements special process-specific tasks in a customer-focussed and professionally-skilled manner — a newly generated function can be easily integrated into the control system as an Add-on.

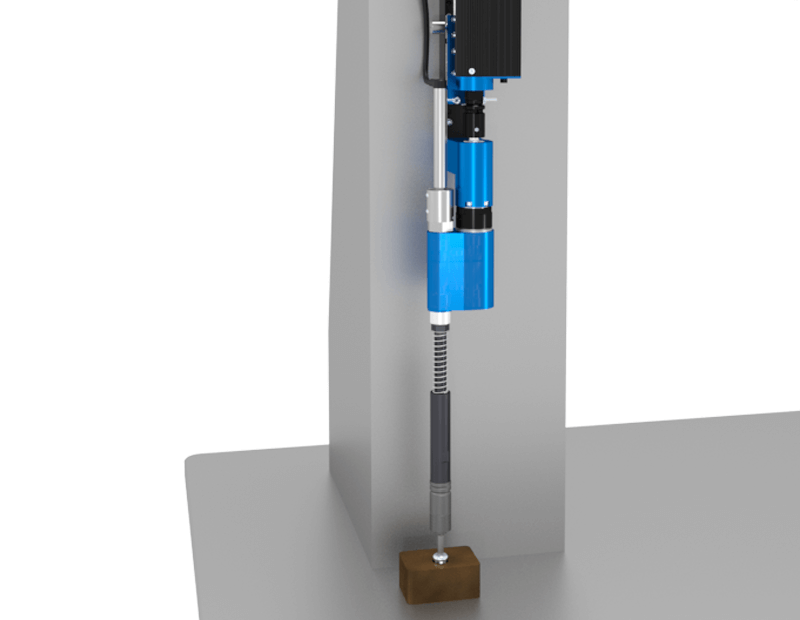

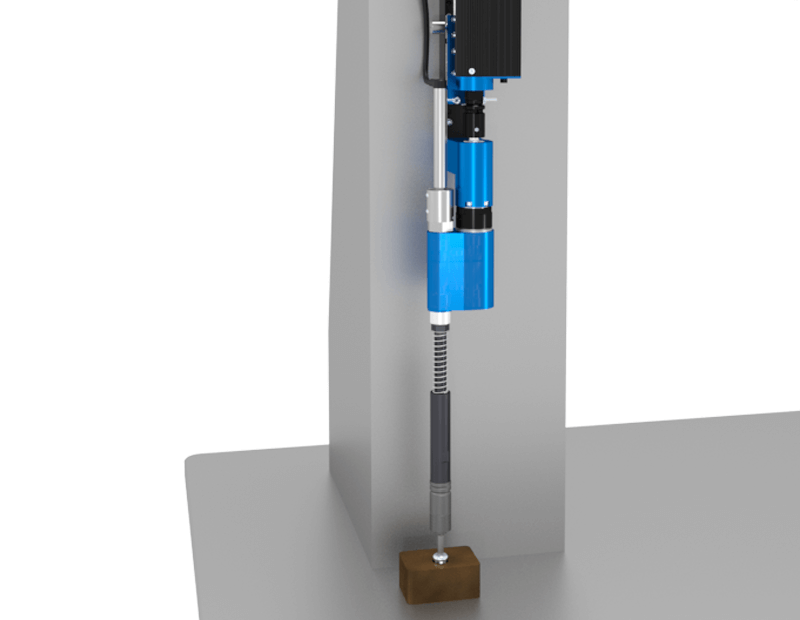

Tightening

The requirements placed on a nutrunner are diverse. The DS series offers you products which are specially configured for your applications.

In the right size, with the correct torque, in the required precision, with the appropriate attachment. Thanks to in-house production, individual adjustments can also be made.

The data transmission is performed digitally for nutrunners from the DS series.

The benefit: The nutrunner features an independent distributed intelligence and only one connecting cable is needed in the power classes up to 60 Nm.

Another striking detail is the light units on the nutrunner which indicate the tightening status.

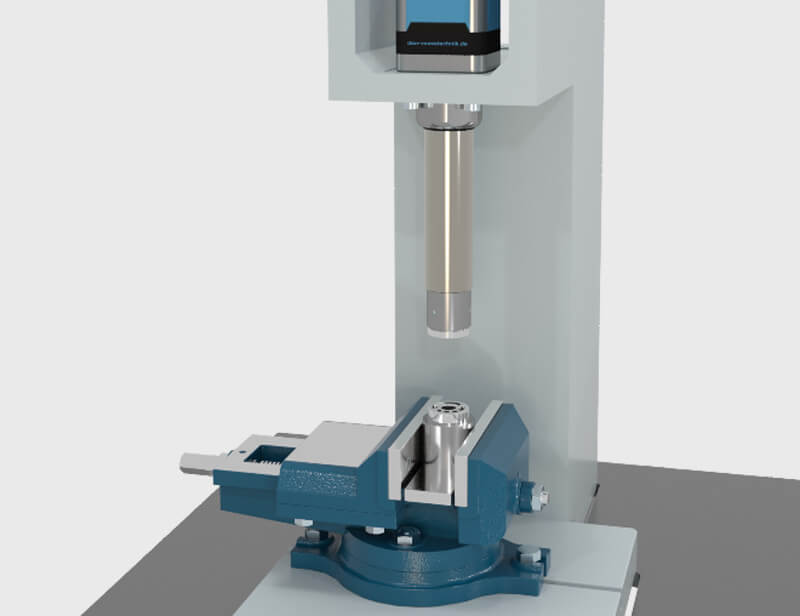

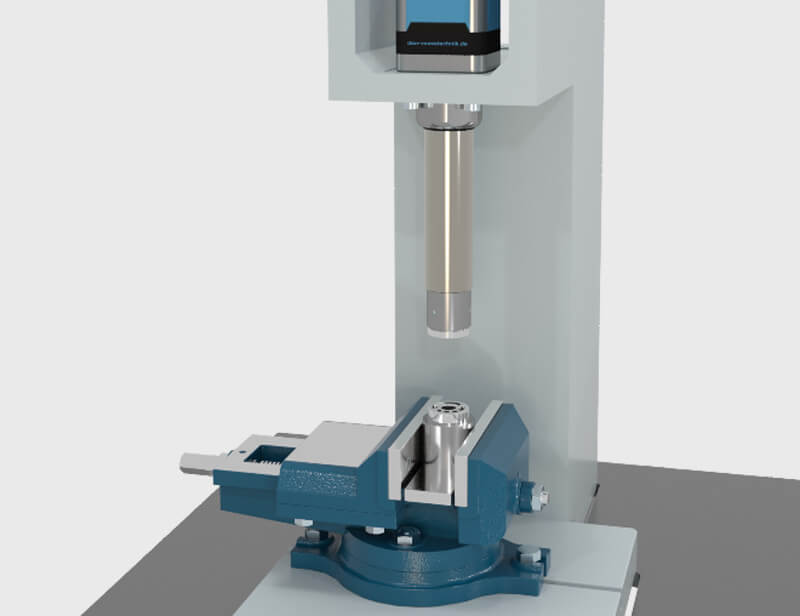

Press-in

The right press-in unit for press, joining and forming tasks. With the QMP and SMP series, DSM offers you joint units which are specially configured for your applications.

In the right size, with the correct force, in the required precision, with an appropriate joining stroke.

In the field of electromechanical press-in units, DSM covers a force range of 50 N to 120,000 N.

In line with requirements, we equip the press-in unit with a greater stroke, return stop or electromechanical brake.

Thanks to in-house production, customer-specific designs are possible.