Key Takeaways

- Definition of torque: Torque is a physical quantity that indicates how strongly a rotational movement acts on a body and is measured in Newton meters (Nm).

- Torque calculation: Torque (M) is calculated as the product of force (F) in Newtons and lever arm (l) in meters: M = F × l.

Torque is a measure of the rotational force applied to an object, often expressed in units like Newton-meters (N m) or foot-pounds (ft-lb).

In the context of bolts, screws, and nuts, torque is crucial for ensuring proper assembly and maintaining the integrity of the joint.

However, not every screw has the same strength class or thread size, which is why the required torque also varies.

Screw and Bolt Torque Table for Standard Threads

The recommended tightening torques below are a great starting point for figuring out how much torque you need.

Please note:

Keep in mind that you might need to adjust these numbers depending on the specific connection or how much lubrication is used on the fasteners.

This Chart gives the suggested maximum torque values for threaded products, but it’s just a reference.

| Thread Size | Torque for Standard Threads in [N m] | ||||||

|---|---|---|---|---|---|---|---|

| Bolt Grade | 3.6 | 4.6 | 5.6 | 6.8 | 8.8 | 10.9 | 12.9 |

| M2 | 0,1 | 0,13 | 0,16 | 0,26 | 0,35 | 0,49 | 0,59 |

| M2,5 | 0,2 | 0,27 | 0,34 | 0,54 | 0,72 | 1,01 | 1,21 |

| M3 | 0,35 | 0,48 | 0,60 | 0,96 | 1,28 | 1,80 | 2,16 |

| M4 | 0,81 | 1,12 | 1,39 | 2,23 | 2,97 | 4,18 | 5,02 |

| M5 | 0,6 | 2,26 | 2,83 | 4,52 | 6,03 | 8,48 | 10,18 |

| M6 | 2,8 | 3,84 | 4,80 | 7,69 | 10,25 | 14,41 | 17,29 |

| M7 | 5,13 | 6,42 | 10,27 | 13,70 | 19,25 | 23,10 | |

| M8 | 9,35 | 11,69 | 18,70 | 24,93 | 35,06 | 42,07 | |

| M10 | 18 | 23 | 37 | 49 | 70 | 83 | |

| M12 | 32 | 40 | 65 | 86 | 121 | 146 | |

| M14 | 52 | 65 | 104 | 138 | 194 | 233 | |

| M16 | 81 | 101 | 161 | 215 | 302 | 363 | |

| M18 | 112 | 139 | 222 | 296 | 417 | 500 | |

| M20 | 157 | 197 | 315 | 420 | 590 | 709 | |

| M22 | 215 | 269 | 430 | 574 | 807 | 968 | |

| M24 | 272 | 340 | 544 | 726 | 1020 | 1224 | |

| M27 | 400 | 500 | 800 | 1067 | 1500 | 1800 | |

| M30 | 542 | 677 | 1083 | 1445 | 2032 | 2438 | |

| M33 | 739 | 923 | 1477 | 1969 | 2770 | 3323 | |

| M36 | 948 | 1185 | 1896 | 2528 | 3555 | 4266 | |

| M39 | 1229 | 1536 | 2457 | 3276 | 4607 | 5529 | |

| M42 | 1519 | 1899 | 3038 | 4050 | 5696 | 6835 | |

| M45 | 1898 | 2373 | 3796 | 5062 | 7118 | 8541 | |

| M48 | 2282 | 2853 | 4565 | 6086 | 8559 | 10271 | |

| M52 | 2954 | 3692 | 5907 | 7876 | 11076 | 13292 | |

| M56 | 3672 | 4591 | 7345 | 9793 | 13772 | 16526 | |

| M60 | 4582 | 5728 | 9164 | 12219 | 17183 | 20619 | |

| M64 | 5536 | 6920 | 11071 | 14762 | 20759 | 24911 | |

| M68 | 6720 | 8400 | 13440 | 17919 | 25199 | 30239 | |

Bolt torque calculator

Select thread size and bolt grade to display the tightening torque for standard threads in [Nm].

DSM bolt torque calculator

What is torque?

Torque is a physical force that indicates how strongly a rotational movement affects an object.

Formula symbol:

The formula symbol for torque is M.

How can you calculate torque for bolts?

For those without a reference book at hand, it is always possible to calculate the tightening torque yourself.

The torque, or tightening moment, is expressed in Newton meters [Nm].

Calculation of Newton meters

{Nm=1{\frac {kg * m^{2}} {s^{2}}}}To calculate the torque (M) in Newton meters [N m], you will need the force (F) in Newtons [N] and the lever arm distance (l) measured perpendicular to the line of action in meters [m].

Formula for calculating torque

M=F * lThe direction of the torque is indicated by + (counterclockwise) and — (clockwise).

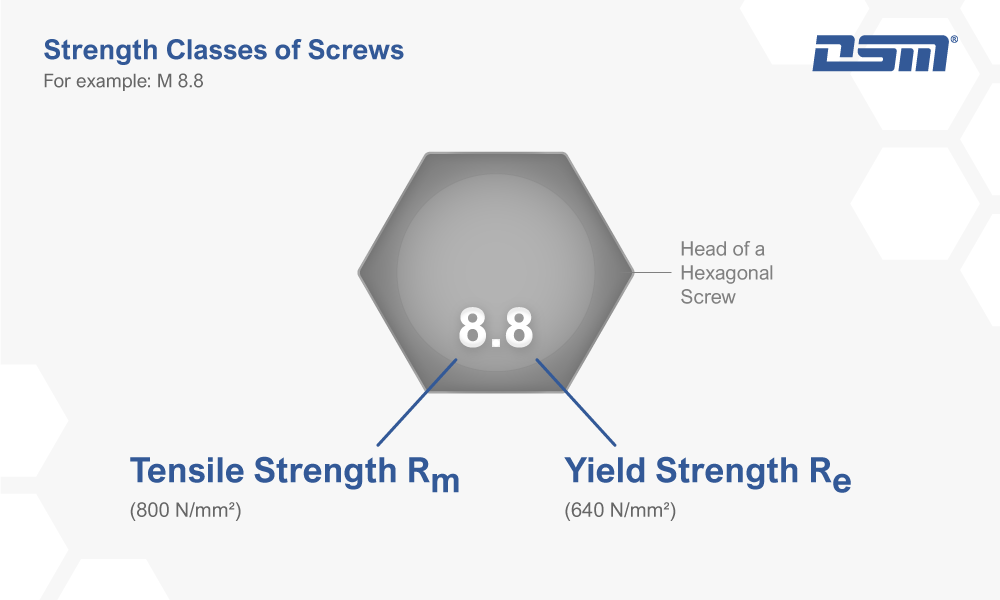

What strength classes are there?

The strength classes of screws determine their tensile strength {R_m} and yield strength {R_e}.

The class is represented on the screw head by two numbers separated by a dot.

In this representation, the left number signifies the tensile strength, and the right number represents the yield strength.

Thanks to the various number combinations, different types of bolts can be compared with each other.

How to calculate tensile strength?

To calculate tensile strength, simply multiply the left number of the strength class by 100.

Calculating tensile strength

{R_m}=leftNumber * 100 or {R_m}={\frac N {mm^2}}

How to calculate yield strength?

To calculate yield strength, multiply the left and right numbers, and then multiply the result by 10.

Calculating yield strength

{R_e = leftNumber * rightNumber * 10}Table of strength classes of bolts

The following table includes all the strength classes mentioned in the screw torque table, along with their corresponding tensile strength and yield strength.

| Strength Class | Tensile Strength | Yield Strength |

|---|---|---|

| 3.6 | 3 x 100 = 300 N/mm² | 3 x 6 x 10 = 180 N/mm² |

| 4.6 | 4 x 100 = 400 N/mm² | 4 x 6 x 10 = 240 N/mm² |

| 4.8 | 4 x 100 = 400 N/mm² | 4 x 8 x 10 = 320 N/mm² |

| 5.6 | 5 x 100 = 500 N/mm² | 5 x 6 x 10 = 300 N/mm² |

| 5.8 | 5 x 100 = 500 N/mm² | 5 x 8 x 10 = 400 N/mm² |

| 6.8 | 6 x 100 = 600 N/mm² | 6 x 8 x 10 = 480 N/mm² |

| 8.8 | 8 x 100 = 800 N/mm² | 8 x 8 x 10 = 640 N/mm² |

| 9.8 | 9 x 100 = 900 N/mm² | 9 x 8 x 10 = 720 N/mm² |

| 10.9 | 10 x 100 = 1000 N/mm² | 10 x 9 x 10 = 900 N/mm² |

| 12.9 | 12 x 100 = 1200 N/mm² | 12 x 9 x 10 = 1080 N/mm² |

Which strength class suits which screw?

Screws made of aluminum, stainless steel, and titanium possess different properties due to their distinct materials.

The following table is intended to assist in assigning them to their respective strength classes.

| Type of Screws | Strength Class |

|---|---|

| Aluminum Screws | 5.6 |

| V2A Screws (stainless steel) | 6.8 |

| Titanium Screws | 8.8 |

FAQ

When does a screw break?

When the permissible yield strength is exceeded, the screw begins to deform, eventually leading to the breaking of the screw.

What is the torque for steel rims?

The correct torque for the wheel bolts of a steel rim on a vehicle can be found in the vehicle manual. However, it usually ranges between 80 and 160 Newton meters.

How much N m can be applied by hand?

Using a screwdriver, a minimum torque of 30 N m can be achieved. The longer the lever, the greater the force that can be applied.

Which screws should be tightened with how much N m?

To find out which screws should be tightened with how much torque, it’s worth taking a look at the screw torque table depicted above. There, screws with their respective strength classes and corresponding torques can be easily read.

Where do I find the tightening torque?

Normally, each manufacturer specifies the permissible tightening torque of the screws on the packaging. If that’s not the case, it can be found in a screw torque table.

Why do I need a torque testing device for nutrunner?

Torque testing devices verify the accuracy of torque wrenches, electric nutrunner, and cordless nutrunner so that they can be calibrated accordingly.

Looking for a reliable tightening technique?

We have a solution for every application case!