Control systems

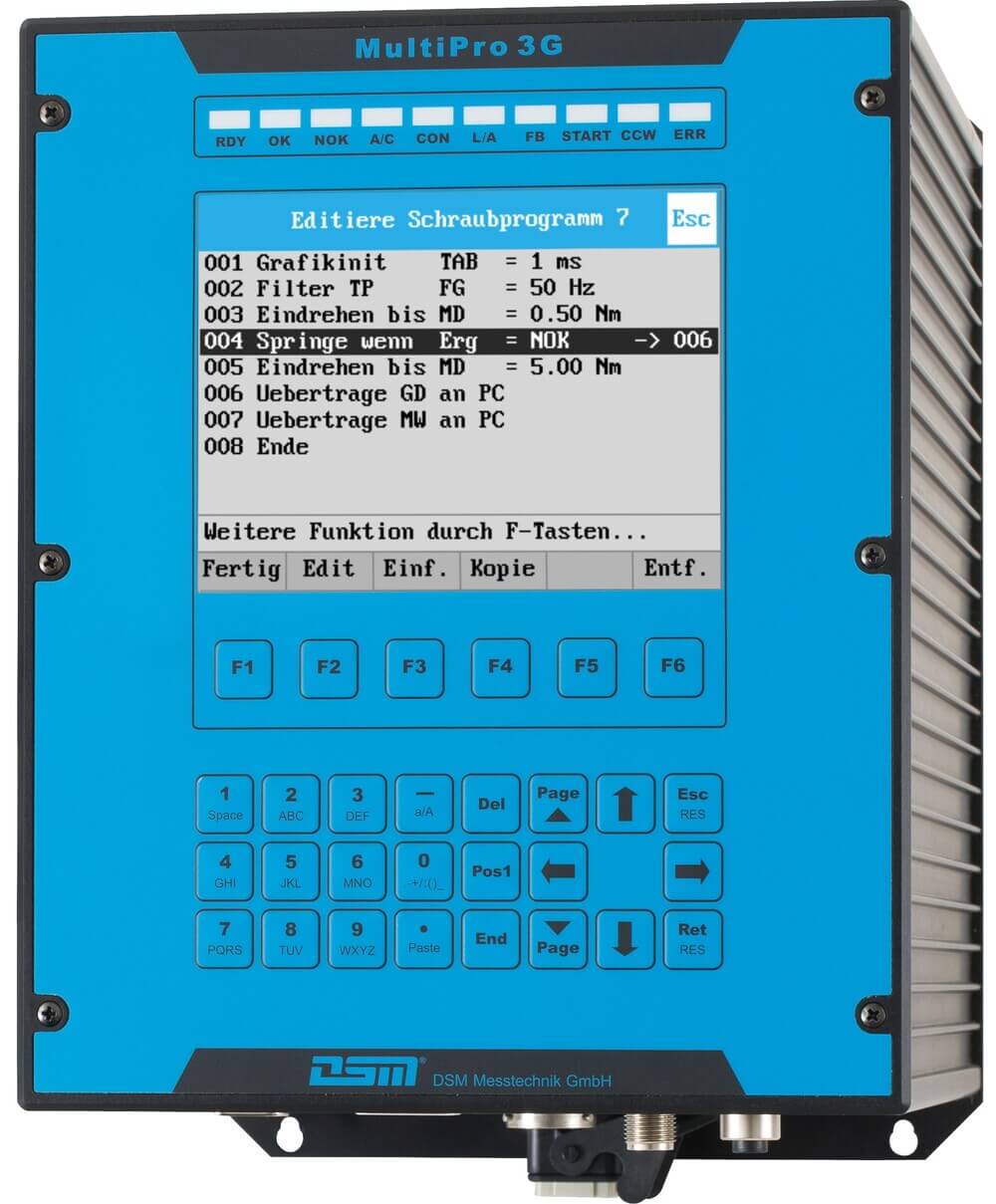

MultiPro 3G

The MultiPro 3G is the central control system for built-in nutrunners and handheld nutrunners of the DS(H) series as well as for all press-in units of the QMP, SMP and XMP series.

Its compact design allows for space-saving use without a control cabinet. The control module and basic module together form a modular platform that can be flexibly adapted to new requirements via expansion slots.

In addition to the hardware extensions, the scalable firmware largely determines the system’s range of functions. An integrated license management system enables configuration as either a tightening or press-in system.

Through extension levels, tool licences, and function extensions, the system can be precisely tailored to the specific application.

Even in its standard configuration, the MultiPro 3G offers a wide range of basic functions. Additional processes and features are already embedded in the firmware and can be activated as needed – also temporarily for testing purposes.

DSM implements process-specific requirements with customer focus and technical expertise – enabling new functions to be integrated quickly and seamlessly into the control system.

The control module handles parameterization, programming, monitoring, and communication within the modular MultiPro 3G platform.

In combination with the basic module, the system can be precisely adapted to a wide range of assembly and testing processes.

Thanks to hardware extensions and integrated firmware, it is flexibly configurable and can be adapted to the DSM tool in use via tool licenses – whether sensor-controlled or current-controlled.

The current-controlled version (SA) is available for almost all nutrunners; for press-in units, the XMP series is available in an SA variant.

This makes the system suitable for a broad spectrum of tightening and press-in tasks with varying levels of process complexity.

The MultiPro 3G control module is equipped with a color touch display and offers a clear menu structure with internationally understandable icons.

This allows intuitive operation and monitoring of processes – regardless of the application scenario.

Depending on the extension level, configuration and programming are carried out either directly via the display or using DSM’s MPEC software.

In simpler versions (e.g. extension level S or M), MPEC serves as the central user interface.

Thanks to integrated interfaces (e.g. Profinet, Ethernet/IP), the system can be connected to higher-level networks and enables centralized parameterization, process monitoring, and data acquisition – ready for connected applications in line with Industry 4.0.

Technical Data

- Display: 5.7‑inch color touch display, resolution 320 x 240 pixels, TFT with 262k colors

- Visualization: Graphical display of measurement values with zoom function

- Status Indicators: 12 status LEDs for system state indication

- Controls: Function keys, navigation keys, and alphanumeric keypad

- Calibration: Traceable calibration; automatic calibration check of the measurement sensor

- Programming: Directly on the device or via MPEC software

- Program Sequences: Freely programmable process sequences, single-step mode for program testing

- Self-Test: Automatic self-test of the control system and connected DSM tool

- Memory: Ring buffer with result storage on the device; measurement results of all steps can be stored

- Messages and Statistics: Message memory and statistical data storage for each step

- External Storage (optional): Backup and production data storage via USB memory stick

- Communication: Integrated TCP/IP module – LAN communication with MPEC software

- System Bus: Interface for system bus devices (accessories) and networking of MultiPro 3G control systems

Hardware Extensions

- Profinet module for integration into the fieldbus system

- EtherCAT module for integration into the fieldbus system

- Profibus module for integration into the fieldbus system

- Measurement module for the connection of external sensors

- IPC/Gateway module for use as OPC UA server, worker guidance, web server …

- BT module for connection with a Bluetooth®-enabled device

- WLAN module for integrating the MultiPro 3G into a WLAN network or for using the MultiPro 3G as a WLAN access point

- USB memory stick Industrial Grade SLC for use as backup and production storage

Extension Level

- Extension Level S (Small) – Programming only on the PC via the MPEC software, 16 startable programs, Measured data storage for 50 data sets (ring buffer), Graphics memory for 5000 measuring points per graphic curve

- Extension Level M (Medium) – Programming only on the PC via the MPEC software, 64 startable programs, Measured data storage for 500 data sets (ring buffer), Graphics memory for 10000 measuring points per graphic curve

- Extension Level L (Large) – Programming directly on the device or via PC using the MPEC software, 128 startable programs, Measured data storage for 1000 data sets (ring buffer), Graphics memory for 20000 measuring points per graphic curve

The individual features of the extension level can also be activated at a later date by means of individual licences. For example, it is possible to implement the feature “Programming on the unit (licence for programme editing)” into the extension level S.

Tool Licence(s)

- Sensor controlled MDW – Use of the MultiPro 3G with

MDW nutrunners (direct torque measurement) - Sensor controlled FL – Use of the MultiPro 3G with

force / stroke controlled press-in units - Current controlled SA – Use of the MultiPro 3G with

SA nutrunners (indirect torque measurement) or SA press-in units of the XMP series (indirect force measurement)

Function Extensions

Flexible in price and performance with the DSM licence model

… only as much as you actually need.

- Result selection – With the result selection you specify the result values for the evaluation of the process. This will evaluate the result relevant to your process.

- Unit adjustable – The unit of torque / force can be set.

- Filter – DSM filter functions for blending out high-frequency (unwanted) interferences of the measuring signal.

- Gradient detection – Function for detection of a defined gradient, detects positive as well as negative peaks and their quantity.

- Direct control via fieldbus – Controls the DSM tool by the specifications in the dynamic fieldbus protocol via fieldbus with the PLC.

- Cyclic values via fieldbus – The measured values selected in the dynamic fieldbus are transmitted cyclically to the fieldbus in real time.

- Parameter via fieldbus (dynamic) – Defined parameters of a stage can be temporarily modified at runtime via the fieldbus.

- Parameter via fieldbus (static) – Defined parameters of a stage can be permanently modified via the field bus.

- Correction factor MD / F – The correction factor serves to matching the torque / force.

- Envelope – Additional evaluation element for control of the process. The measuring curve may not break the upper and/or lower envelope.

- Linearisation MD – Linearisation / multi-range calibration Torque with higher accuracy requirements for specific torque points.

- Linearisation WI – Linearisation / multi-range calibration Rotation angle to compensate for occurring torsional losses.

- Yield strength procedure – Tighten until the defined switch-off gradient is reached.

- Head contact – Tighten to head contact with the specially developed DSM algorithm for head contact detection for self-forming / self-tapping tightening processes.

- Thread entry detection – Rotation against the screw-in direction – detection of the jump of thread entry into the first thread by using a length measuring sensor.

- Turn in to external sensor – Tightening until a defined external target value is reached with monitoring of torque and angle of rotation.

- Turn and hold – After switch-off, the torque or the position (angle of rotation) measured at this time is held for a defined period of time.

- Linearisation F – Linearisation / multi-range calibration Force with higher accuracy requirements for specific force points.

- Linearisation L – Linearisation / multi-range calibration Length (stroke) for compensation of load-dependent deflection.

- Press and hold – After switch-off, the force or the position (length) measured at this time is held for a defined period of time.

- Move to external sensor – Press-in until a defined external target value is reached with monitoring of force and length. For example for the direct and high-precision measurement on the component with an external length sensor; measures the actual stroke (relative height), regardless of influences such as bending, different heights or tolerances on the tool carrier.

- Move to gradient – Move until the defined switch-off gradient [kN/ms] is reached – display of the gradient curve with the second Y axis. Control of force and length.

- Review window – The function can be used to generate a window within a procedure, which is defined by means of a start and end value and evaluated retrospectively.

…

Accessories

- MultiVisio – MultiPro 3G remote display (Android app).

- IO Extension – extension of the inputs and outputs.

- IO Expander – for comfortable connection of components.

- QS Box – connection of external sensors to the MultiPro 3G.

- ToolControl – tool management, monitoring of tool removal.

- Handling System / Position Electronics – for monitoring XYZ coordinates, the position sequence.

- Status Indication – external status display, optionally with start button, programme preselection, NOK key switch.

- DCM Extension – for controlling an external DC motor.

The basic module supplies power to both the control module and the connected DSM tool (nutrunner or press-in unit). It also regulates and monitors the drive, checks the voltage, monitors the condition of the Hall sensors, and controls the temperature, current, and voltage of the servomotor.

Depending on the required performance level, different types of basic modules are available. Each DSM tool is assigned a specific basic module type. The basic module with STO (Safe Torque Off) safety function is designed for integration into customer-specific safety concepts.

Our press-in systems are equipped as standard with basic modules featuring STO functionality and comply with the requirements of DIN EN ISO 13849.

The modular system design not only allows easy replacement of the control module (e.g. upgrade to MultiPro 3G), but also enables the basic module to be exchanged in response to changing process conditions – ensuring maximum flexibility in application.

BM‑S Series Executions

Basic module BM-S‑1 / Basic module BM-S-1-STO

for DSH 26 /005; DS 26 /005

Basic module BM-S‑2 / Basic module BM-S-2-STO

for DSH 26 /01/02/04; DS 26 /01/02/04; DSH 28 /012/022/05

Basismodul BM‑S‑3 / Basismodul BM-S-3-STO

für DS 26 /03

Basismodul BM‑S‑4 / Basismodul BM-S-4-STO

für DSH 28 /006

Basic module BM-S‑5

for DSH 16 /0025/005

Mains voltage 230 VAC

W x H X D (without STO) 201 x 279,5 x 128 mm

W x H X D (with STO) 201 x 279,5 x 231 mm

Weight approx. 5 kg

BM‑L Series Executions

Basic module BM-L‑1 / Basic module BM-L-1-STO

for DS 34 /025/05

Basic module BM-L‑3 / Basic module BM-L-3-STO

for DS 44 /025/05/10/20; SMP 300 /005/01/02; XMP 60 /005/01/02

Basic module BM-L‑4 / Basic module BM-L-4-STO

for DSH 34 /05/10/20; DS 34 /10/15; DSH 38 /05/10/15; DSH 44 /20/30/40/60

Basic module BM-L‑5 / Basic module BM-L-5-STO

for DS 44 /35

Mains voltage 230 VAC

W x H X D 201 x 279,5 x 231 mm

Max. weight approx. 14 kg

BM‑H Series Executions

Basic module BM-H-2-STO

for SMP 400 /05/10

Basic module BM-H‑4 / Basic module BM-H-4-STO

for DS 57 /25/50/70/90/140

Basic module BM-H-5-STO

for XMP 90 /05/12,5/25; QMP 80 /025/05/10/20/25

Mains voltage 230 VAC

W x H X D 201 x 279,5 x 231 mm

Weight approx. 8 kg

BM‑V Series Executions

Basic module BM-V‑4 / Basic module BM-V-4-STO

for DS 80 /220/300/420/500/600; DS 80–130 /900/1000/1500/2000/2400

Basic module BM-V-5-STO

for QMP 100 /30/40/50/60; QMP 140 /70/100/120; SMP 500 /20/30/50/70

Basic module BM-V-7-STO

for XMP 120 /30/50/75/100; XMP 300 /125/250/300

Mains voltage 400 VAC

W x H x D 201 x 279,5 x 231 mm

Weight approx. 8,5 kg