Press-in technique

The SMP series

Press-in units o the SMP series are exclusively designed for compressive forces and are very robust and low-maintenance.

The simple design is convincing in the harsh industrial environment.

The digital load cell is positioned in the direct vicinity of the plunger. The stroke is measured via an absolute stroke measuring system.

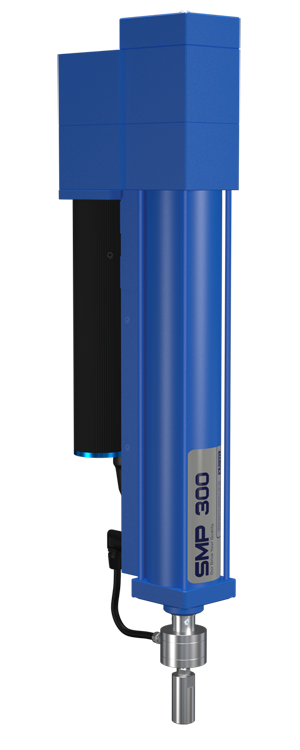

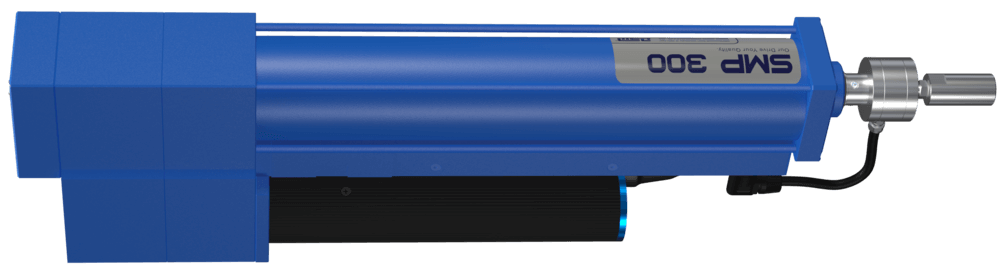

SMP 300 series

Press-in unit with brushless, electronically controlled servo motor, digital force sensor and absolute stroke measuring system.

Available in the basic design with 100 mm, 200 mm or 400 mm stroke. Available nominal forces: 0.25 kN, 0.5 kN, 1 kN and 2 kN in compressive design.

Features

- Servo motor, motor attachment angled via motor offset for compact design

- Force sensor direct-acting, installed on the plunger

- Precision of force measurement 1% of the final value

- Displacement sensor (absolute encoder) directly fitted on the ball screws

- Distance repeat precision 0.01 mm at approx. 20 mm/s

- Distance measurement resolution 0.003 mm

- Stamping speed max. 350 mm/s in both directions continuously variable

Accessories

- Sealing air connection – avoids the ingress of dirt particles into the press-in unit

- Portal frame manufactured according to customer-specific requirements

- C‑frame manufactured according to customer-specific requirements

- Service package – lubrication set

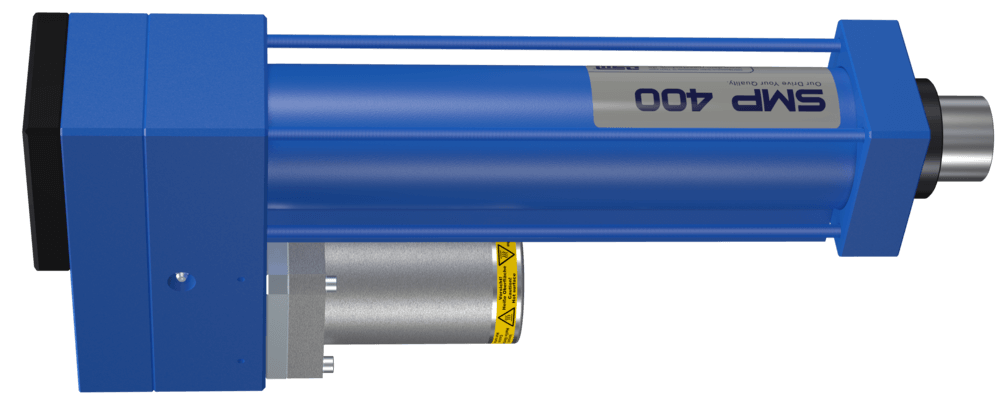

SMP 400 series

Press-in unit with brushless, electronically controlled servo motor, digital force sensor and absolute stroke measuring system.

Available in the basic design with 100 mm, 200 mm or 400 mm stroke. Available nominal forces: 5 kN and 10 kN in compressive design.

Features

- Servo motor, motor attachment angled via drive offset for compact design

- Force sensor direct-acting, installed on the joint plunger

- Precision of force measurement 1% of the final value

- Displacement sensor (absolute encoder) directly fitted on the ball screws

- Distance repeat precision 0.01 mm at approx. 20 mm/s

- Distance measurement resolution 0.003 mm

- Stamping speed max. 200 mm/s in both directions continuously variable

Standard options

- Motor holding brake for higher tool weight

Accessories

- Fan unit for cooling the motor

- Sealing air connection – avoids the ingress of dirt particles into the press-in unit

- Portal frame manufactured according to customer-specific requirements

- C‑frame manufactured according to customer-specific requirements

- Service package – lubrication set

SMP 500 series

Press-in unit with brushless, electronically controlled servo motor, digital force sensor and absolute stroke measuring system.

Available in the basic design with 100 mm, 200 mm or 400 mm stroke. Available nominal forces: 20 kN, 30 kN, 50 kN and 70 kN in compressive design.

Features

- Servo motor, motor attachment angled via drive offset for compact design

- Force sensor direct-acting, installed on the plunger

- Precision of force measurement 1% of the final value

- Displacement sensor (absolute encoder) directly fitted on the ball screws

- Distance repeat precision 0.01 mm at approx. 20 mm/s

- Distance measurement resolution 0.003 mm

- Stamping speed max. 150 mm/s in both directions continuously variable

Standard options

- Motor holding brake for higher tool weight

Accessories

- Fan unit for cooling the motor

- Sealing air connection – avoids the ingress of dirt particles into the press-in unit

- Portal frame manufactured according to customer-specific requirements

- C‑frame manufactured according to customer-specific requirements

- Service package – lubrication set