Tightening technique

Built-in nutrunners DS series

Great products are the result of flawless processes. In the case of industrial manufacturing, perfect production is paramount.

Screw connections in particular should not cause product deficiencies. Digital tightening technique from DSM is a solid choice for high quality.

All DSM products are characterised by their perfect integration into new or existing production lines.

The DSM experts for built-in tightening technique support projects of our customers, from the planning phase, through to commissioning and of course beyond.

Built-in tightening technique from DSM

- Digital tightening technique

- Built-in nutrunners from 0.05 Nm to 2400 Nm

- Error-free setup through integrated parameter memory

- Maintenance-free brushless servo motor, clockwise / anti-clockwise

- Robust housing made of stainless steel and aluminium

- Diverse drive and attachment versions

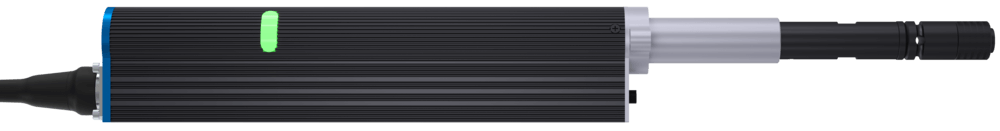

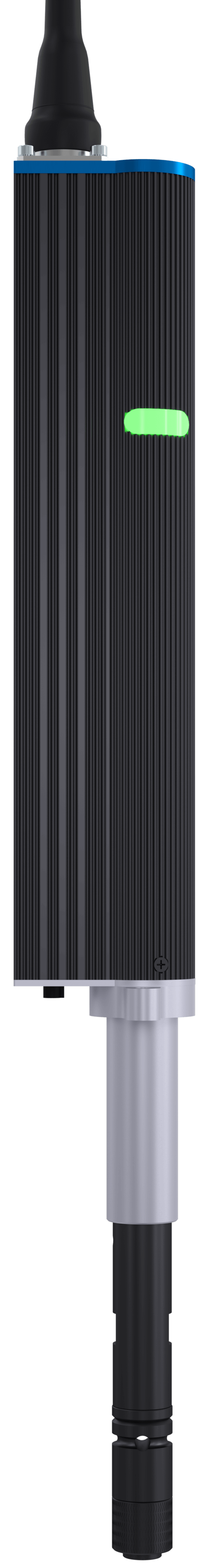

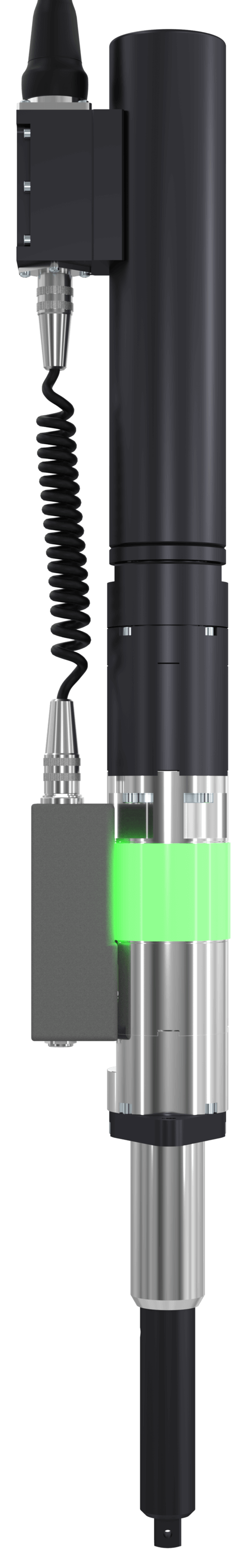

DS 26 series

Built-in nutrunner with electronically controlled servo motor and digital data transmission. Available in torque versions of 0.5 Nm, 1 Nm, 2 Nm and 4 Nm.

- Status indicator over light field

- Motor and gear are integrated in an aluminium housing

- Speed continuously variable, clockwise / anti-clockwise

MDW design

- Torque measurement direct via digital sensor

- Measurement precision of torque: 0.5% of final value

- Rotational angle recording via motor sensors

- Angle resolution: 3.7° (DS26/005, 26/01); 2.6° (DS26/02); 1.0° (DS26/04)

SA design

- Torque measurement indirect via power-off

- Measurement precision of torque: 5% of final value

- Rotational angle recording via motor sensors

- Angle resolution: 4.3° (DS26/005, 26/01); 2.1° (DS26/02); 1.0° (DS26/04)

Standard options

- Output offset

- Stub output

- Spring output

- Self start output

- Angle head

- Vacuum screw-retainer

- Output unit with galvanic isolation

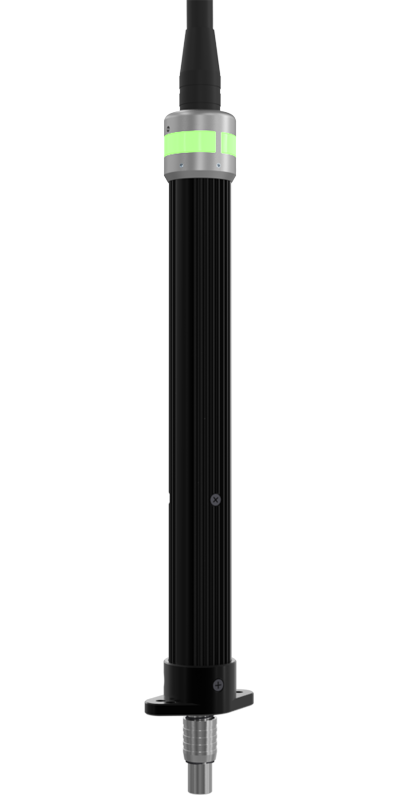

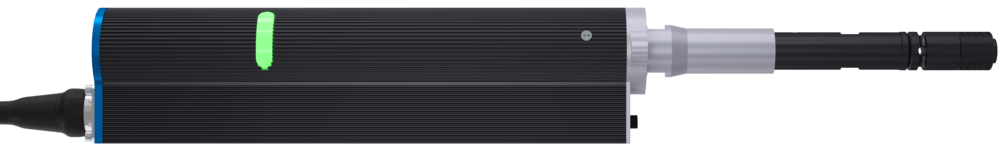

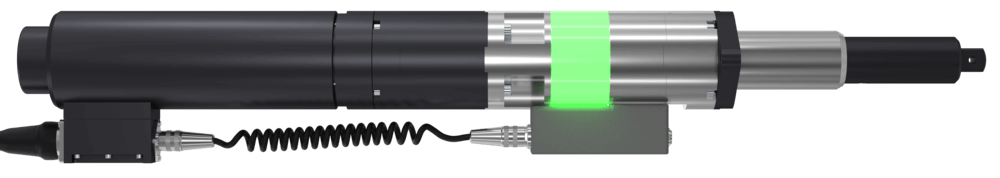

DS 34 series

Built-in nutrunner with electronically controlled servo motor and digital data transmission. Available in torque versions of 2.5 Nm, 5 Nm, 10 Nm and 15 Nm.

- Status indicator over light field

- Motor and gear are integrated in an aluminium housing

- Speed continuously variable, clockwise / anti-clockwise

MDW design

- Torque measurement direct via digital sensor

- Measurement precision of torque: 0.5% of final value

- Rotational angle recording via digital absolute encoder

- Angle resolution: 0.1°

SA design

- Torque measurement indirect via power-off

- Measurement precision of torque: 5% of final value

- Rotational angle recording via motor sensors

- Angle resolution: 3.3° (DS34/025, 34/05); 1.7° (DS34/10, 34/15)

Standard options

- Output offset

- Stub output

- Spring output

- Self start output

- Angle head

- Output unit with galvanic isolation

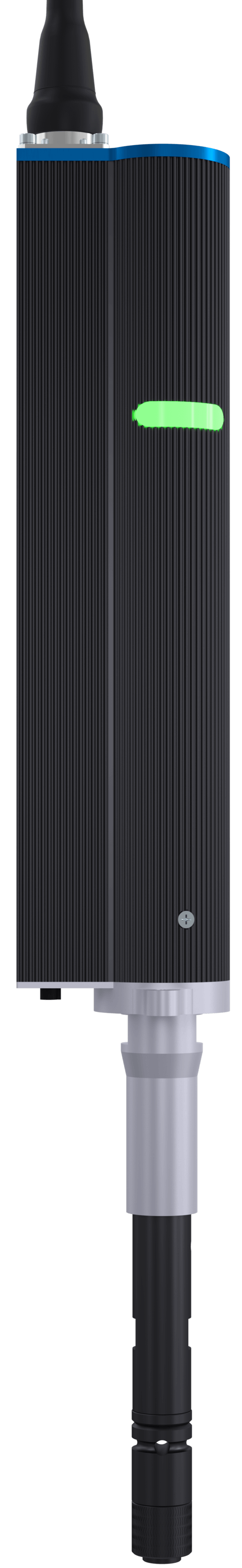

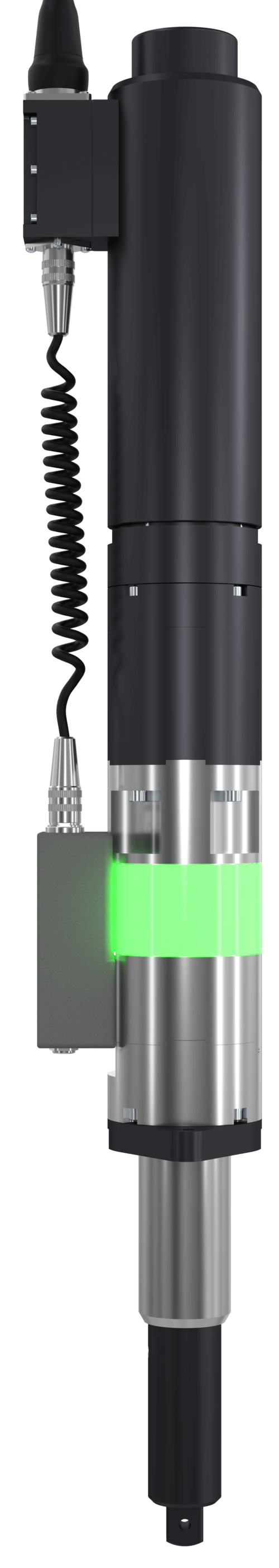

DS 44 series

Built-in nutrunner with electronically controlled servo motor and digital data transmission. Available in torque versions of 2.5 Nm, 5 Nm, 10 Nm, 20 Nm and 35 Nm.

- Status indicator over light field

- Motor and gears are integrated in an aluminium housing

- Speed continuously variable, clockwise / anti-clockwise

MDW design

- Torque measurement direct via digital sensor

- Measurement precision of torque: 0.5% of final value

- Rotational angle recording via digital absolute encoder

- Angle resolution: 0.1°

SA design

- Torque measurement indirect via power-off

- Measurement precision of torque: 5% of final value

- Rotational angle recording via motor sensors

- Angle resolution: 3.3° (DS44/05);

2.3° (DS44/10); 1.4° (DS44/20); 1.0° (DS44/35)

Standard options

- Output offset

- Stub output

- Spring output

- Self start output

- Angle head

- Output unit with galvanic isolation

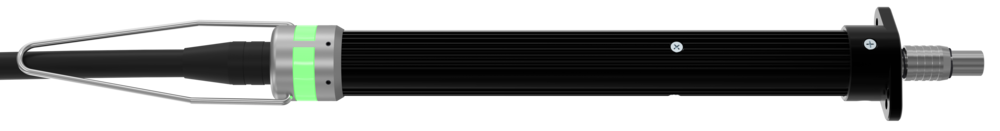

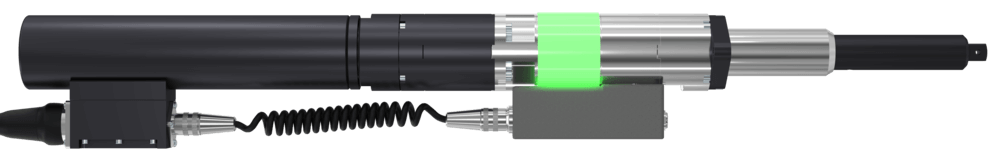

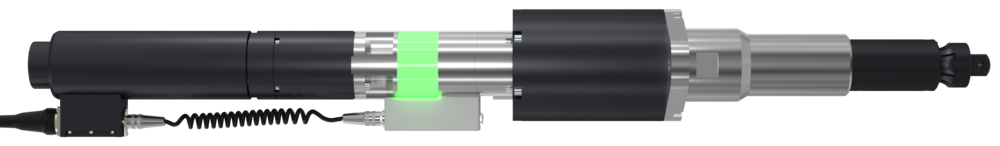

DS 57 series

Built-in nutrunner with electronically controlled servo motor and digital data transmission. Available in torque versions of 25 Nm, 50 Nm, 70 Nm, 90 Nm and 140 Nm.

- Status indicator over light field

- Speed continuously variable, clockwise / anti-clockwise

- Compact design

MDW design

- Torque measurement direct via digital sensor

- Measurement precision of torque: 0.5% of final value

- Rotational angle recording via digital absolute encoder

- Angle resolution: 0.1°

SA design

- Torque measurement indirect via power-off

- Measurement precision of torque: 5% of final value

- Rotational angle recording via motor sensors

- Angle resolution: 4.5° (DS57/25, 57/50);

2.2° (DS57/70); 1.2° (DS57/140)

Standard options

- Motor offset

- Output offset

- Stub output

- Spring output

- Self start output

- Angle head

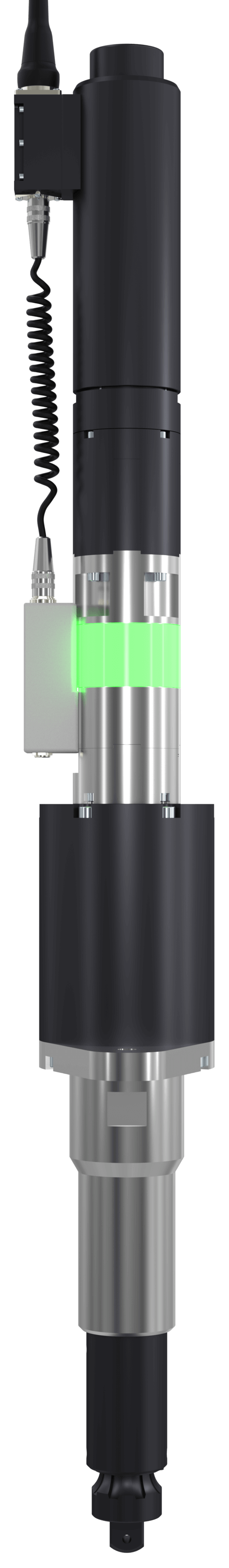

DS 80 series

Built-in nutrunner with electronically controlled servo motor and digital data transmission. Available in torque versions of 220 Nm, 300 Nm, 420 Nm, 500 Nm and 600 Nm.

- Status indicator over light field

- Speed continuously variable, clockwise / anti-clockwise

- Compact design

MDW design

- Torque measurement direct via digital sensor

- Measurement precision of torque: 0.5% of final value

- Rotational angle recording via digital absolute encoder

- Angle resolution: 0.1°

SA design

- Torque measurement indirect via power-off

- Measurement precision of torque: 5% of final value

- Rotational angle recording via motor sensors

- Angle resolution: 1.2° (DS80/220, 80/300);

1.0° (DS80/420, 80/500, 80/600)

Standard options

- Motor offset

- Output offset

- Stub output

- Spring output

- Self start output

- Angle head

DS 80–130 series

Built-in nutrunner with electronically controlled servo motor and digital data transmission. Available in torque versions of 900 Nm, 1000 Nm, 1500 Nm, 2000 Nm and 2400 Nm.

- Status indicator over light field

- Speed continuously variable, clockwise / anti-clockwise

- Compact design

MDW design

- Torque measurement direct via digital sensor

- Measurement precision of torque: 0.5% of final value

- Rotational angle recording via digital absolute encoder

- Angle resolution: 0.1°

SA design

- Torque measurement indirect via power-off

- Measurement precision of torque: 5% of final value

- Rotational angle recording via motor sensors

- Angle resolution: 1.0°

Standard options

- Motor offset

- Stub output

- Spring output