Table of Contents

Accurate thread testing is becoming increasingly important in series production.

Thread testing

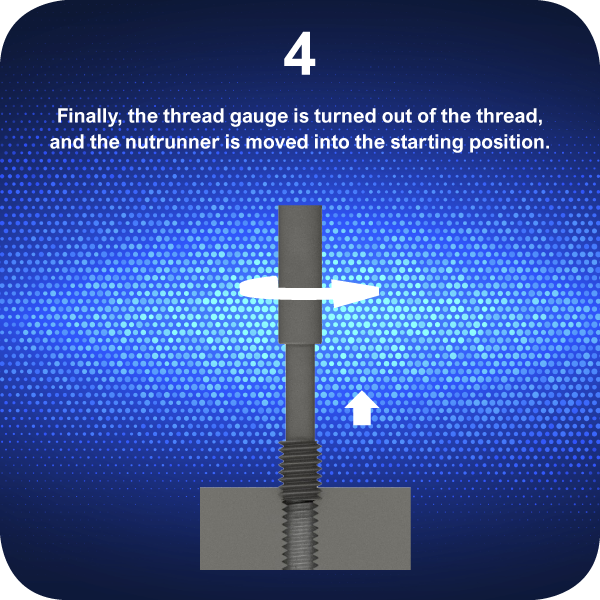

Our thread testing technology is built upon the MultiPro 3G control system and is specifically designed for automated testing of both internal and external threads using thread gauges when paired with our dedicated thread testing nutrunner.

In view of the increasing importance of precise thread testing in modern series production processes, we have developed this technology.

A new dimension in thread testing is opened up by using the DSM test nutrunner with changeable thread gauges in combination with intelligent measurement technique. This not only enables automated and stable testing procedures but also comprehensive documentation of the entire process.

Thanks to the modularity of our nutrunner and control system, the equipment can be flexibly adapted to individual requirements. Whether it’s the nutrunner itself, the low-backlash output adapted to it, an attachable position sensor, or the execution of the thread gauge – our inspection system enables the efficient testing of all threads in your production.

By the way:

The optional monitoring function can also be used in conventional tightening processes, where it is possible to measure and analyse the screw depth in addition to the torque and angle of rotation and use it as a preset parameter.

The benefits of our thread testing solution

- Compact design, based on standard tightening system.

- Flexible test strategy with up to 99 possible test steps.

- Gentle screw-on pressure thanks to spring elements (optional adjustable).

- Storage of up to 128 different test programmes.

- Optional: Special test gauge holder to compensate small alignment errors by decoupling the gauge from the axis of rotation.

- Optional: The automatic changeover unit allows for the automatic switching of the inspection gauge or, in case of a malfunction, its disconnection.

Data sheet

Here you will find the corresponding technical data sheet for our Threat test nutnunner with a example sequence. You can view or download the document directly in the browser.

Meaning (Videoclip)

In the following german explanatory video you will learn why thread testing is so important in the industrial assembly of assemblies and what solutions DSM offers for this.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationCalibration

Did you know that you can have your devices calibrated directly in-house?