Press-in technique

digital Press-in technology for optimum connections

Press-in Technique

DSM Digital Press-In Technology

In the field of electromechanical press-in units, DSM covers a press-in force range of 50 N to 120,000 N. In line with requirements, we equip the press-in units with a greater stroke, return stop or electromechanical brake.

Thanks to in-house production, customer-specific designs are possible.

The distance can be measured relatively or absolutely. The distance measuring procedure to be used is set in the control system.

In digital press-in technology, DSM offers the following series:

Click the respective button to download the form directly. Complete the inquiry form, save it, and send it via email to DSM or upload the saved file through the contact form.

They are particularly used for press-in components in steel construction, aircraft construction, automotive and civil engineering.

Joining — A Simplified Definition

According to DIN ISO 857–1 joining is defined as follows:

Joining refers to the process of connecting or combining two or more separate components to create a unified structure or system.

During this process cohesion is created locally and increased as a whole.

Simply put joining is the permanent connection of two or more workpieces with each other through screws, rivets or bolts.

Joining technology also includes fusion with the help of shapeless materials, for example by using an adhesive.

This results in a connection between workpieces that can be both rigid and movable.

Joining Methods

The DIN 8593 standard includes a categorization of joining and joining technology, respectively into various methods.

These are:

- Putting together

- Filling

- Pressing on/in

- Shapeless forming

- Forming

- Welding

- Soldering

- Bonding

- Textile joining

The following table provides an overview of the individual joining methods and their application fields:

| Joining Method | Definition | Field of Application |

|---|---|---|

| Putting together | Joining, placing, setting, inserting, fitting together, hanging, hooking, aligning, partial spreading of two workpieces. | Assembly |

| Filling | Filling of voids or containers with shapeless materials. | Impregnation |

| Pressing on/in | Elastic deformation of workpieces through screws, clamps, clips, press connections, nailing, wedging, tensioning. | Electrical engineering, mechanical engineering |

| Shapeless forming | Connecting workpieces with an additional workpiece or shapeless material. | 3D-printing |

| Forming | Shaping workpieces through bending, flanging, necking, narrowing, folding, notching, grooving, riveting, spreading, overlapping, widening. | Automotive industry, household appliances industry |

| Welding | Joining workpieces through heat/force with/without filler metal (shielding gas, welding powder, fluxes, pastes) | Automotive industry, mechanical engineering, steel and metal construction |

| Soldering | Creating a surface to alloy through heat. The workpiece itself is not deformed. | Electrical engineering |

| Bonding | Inseparable and material-bonded connection of workpieces through adhesives. | Automotive industry, aerospace |

| Textile joining | Connecting workpieces through form fit, force fit or material fit. | Textile manufacturing |

All press-in units by DSM are designed for the press-in methods of pressing on/in as well as forming.

Application field

Precision press-in, press-in to a stop, riveting, bending, embossing/forming, testing/measuring, caulking, clipping, checking switch/latch points and calibrating.

The DSM press-in technology series covers the following compressive and tensile forces:

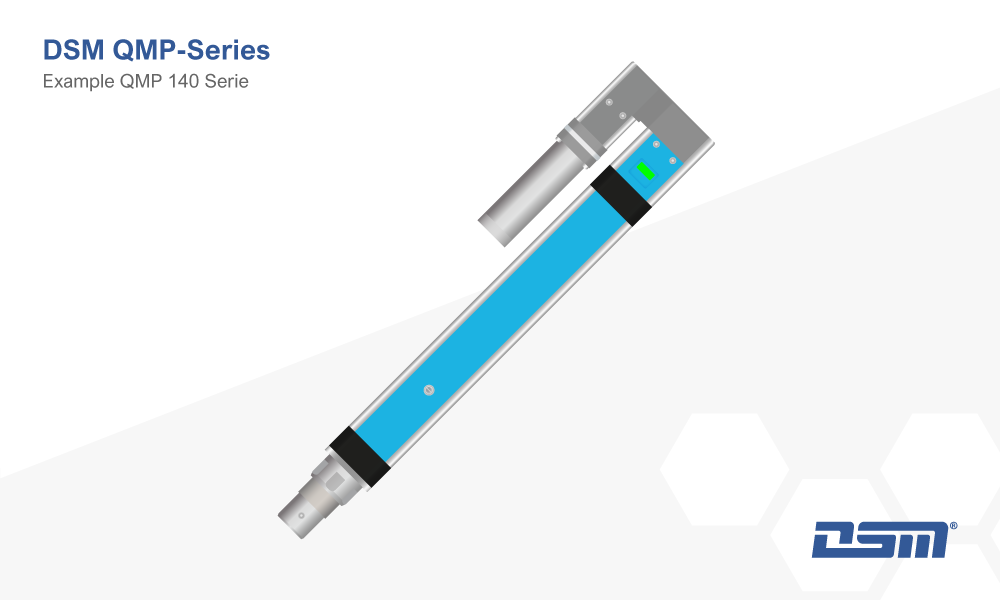

- QMP-Series: 2,5 kN bis 120 kN

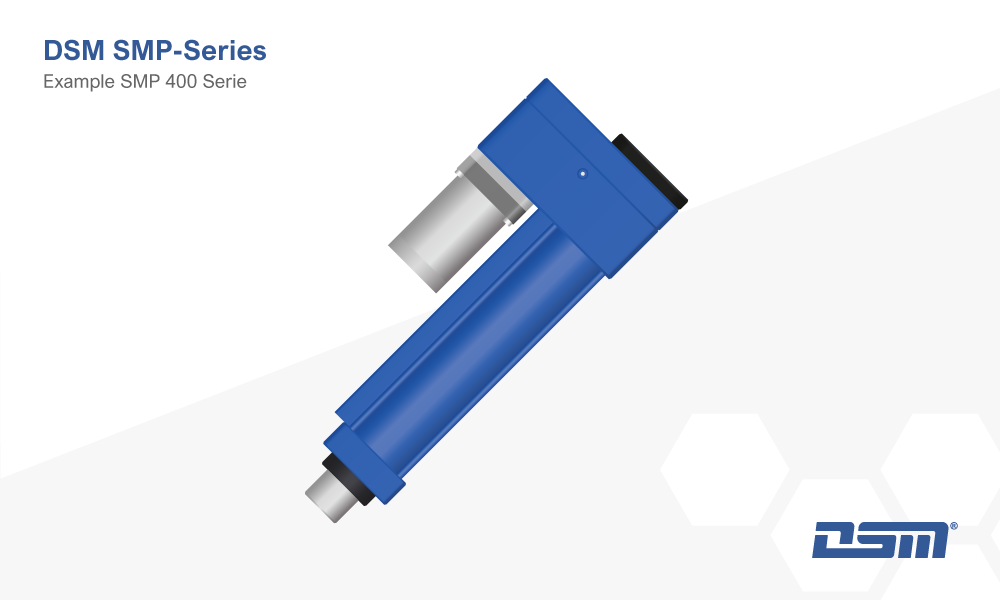

- SMP-Series: 0,25 kN bis 70 kN

- XMP-Series: 5 kN bis 25 kN

Die QMP-Series

The DSM QMP Series is compactly built including a force sensor, a press-in stamp, an absolute distance measuring system and a built-in LED status indicator.

Combined with the MultiPro 3G control system a high assembly accuracy and uninterrupted documentation of production data is guaranteed.

The entire system is powered by a brushless, electronically controlled servo motor.

Forces

For all QMP press-in units the options to choose between compression, tension or compression and tension configurations are available.

Die SMP-Series

The DSM SMP Series is characterized by a robust and low-maintenance design, a digital force sensor and an absolute distance measuring system.

The MultiPro 3G control system ensures a high assembly accuracy and uninterrupted documentation.

Units in this series are powered by a laterally offset, brushless and electronically controlled servo motor.

Forces

All SMP press-in units are exclusively designed for compressive forces.

Die XMP-Serie

The DSM XMP Series is distinguished by a flexible design ensuring tremendous modularity.

A flexible solution for both simple and complex tasks is guaranteed thanks to following components:

- Integrated gear module

- Variable and highly accurate force sensor

- Absolute distance measuring system

- Large illuminated field

- MultiPro 3G control system

XMP press-in units are powered by a brushless electronically controlled servo motor.

Thanks to the modular structure, a motor holding break (MB), a backstop (RS) and a holding brake (HB) can be added additionally.

Forces

The XMP press-in technology is designed for both tensile as well as for tensile and compressive forces.